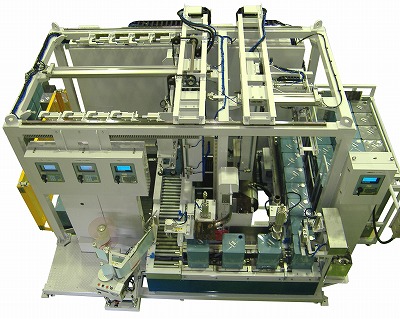

18L can full automatic filling device

OSC 92UL TFM-18APX

Pressure resist explosion proof type

Features

-Fully explosion proof not found in other companies, possible to install all devices within dangerous area.

-As the intrinsically safe specifications it is not necessary to install control panel that houses the barrier at the safe plate, only supplying power and air.

-Wiring and plumbing works to safe place is not necessary which reduces cost.

-From designing/manufacturing of mechanism and system. designing to creation of software is done consistently in house.

-Adopting pressure resist explosion proof PLC for control part enabling to control various action, data acquisition and work together with other system devices are possible.

| 1. De-palletizer |

| -Manually connect dedicated empty can basket to the apparatus. -Automatically transfer empty can from the basket to the apparatus. -Empty can basket stock : max. 72 cans ( 6 cans x 3 lines x 4 stages) |

| 2.Un-capper |

| -Judges whether the can mouth position is adequate or not. Removes metal temporal cap. |

| 3.Filling machine |

| -Executes filling of a certain quantity. -Weighing : Pressure resist explosion proof single point load cell -Capacity/division : 30 kg/0.01 kg -Filling : Input : 2 stages input -Liquid contact part material : SUS304 (packing : Teflon) -Auxiliary equipment : auto drip pan device -Filling capacity : 100 cans/h (*) -Filling accuracy : ±0.1%F.S. (*) (*) With constant flow rate water and filling pressure 0.2 MPa |

| 4.Check balance |

| -Executes re-check of filling quantity. -Pressure resist explosion proof type load cell 1 point -Capacity/division : 30 kg/0.01 kg (National assay applied product) |

| 5. Capper |

| -Automatically mounts caps to filled cans |

| 6. Labeler |

| -Automatically affixes labels to the filled cans. -Checks propriety of affixing by an optical fiber sensor. -Dedicated for side face affixing type vertical type tack label class 1 (roll type) -Affixing capacity : 300 cans/hour |

| 7. Re-capper |

| -Checks whether the cap is correctly fixed and at the same time executes re-pushing of cap.s |

| 8. Palletizer |

| -Loads filled cans onto the pallet automatically. -Pallet size : 1200 mm x 1200 mm x 150 mm (H) -Loading pattern : 5 cans x 5 cans x 3 layers |

PDF Brochure

PDF Brochure