Light Scattering Real Time Dust Density Monitor System

OSC92UM200

<Applications>

- FDG of coal/oil electric power plant

- Iron works

- Waste garbage incinerator

- Cement plant etc.

<Compliance and CSR>

Reducing the dust from a plant/factory, which may cause environmental pollutions and health issues, is global demand.

This monitor system helps to run a plant/factory more cleanly and efficiently and to establish corporative compliance

and CSR.

<Features>

- For the harsh industrial environment such as high temperature (820deg.), high pressure (246kPa) high humid, and highly electrically charged flue gas

- Possible to measure dust density up to 1 mg/Nm³

- Designed both for standalone and integrated in DCS

- Microprocessor analyzes the data from the detector and dispatches alarm signals to the DCS to control the whole factory or to the dust control system

- Reliable monitoring in the harsh conditions with light scattering method

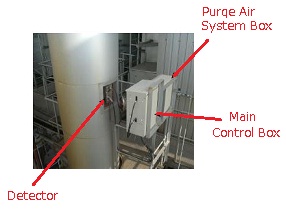

- Simple and easy installation

- Simple and easy maintenance

| MODEL | OSC 92UM200 | |

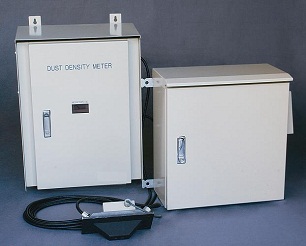

| CONTROL BOX | Structure | Wall mount outdoor installation type |

| Principle | 90 degree back ward light scattering method | |

| Light source | Halogen light | |

| Measurement range | 0 - 500mg/Nm³ relative density output (range is variable) | |

| External output | DC4 - 20mA Isolated output RS-232C | |

| Display | Digital panel meter of 0 - 100% | |

| Power Supply | AC100V+/-10% (50/60Hz), 4A from purge air system box | |

| Operating temperature | -10 - +50 deg. | |

| DETECTOR | Dimension | 260 x 125mm |

| Weight | approx. 5kg | |

| Material | Stainless steel (SUS304) | |

| Attachment | 200 x 65mm rectangle hole is opened and attached to the dust | |

| Connection of purge air | Female screw of PT1/4 (cheese union) | |

| PURGE AIR SYSTEM BOX | Air flow | Approx. 100L/min |

| Power Supply | AC220V +/-10% (50/60Hz), Capacity 1KVA | |

| Operating temperature | -10 - +50 deg. | |

pdf brochure

pdf brochure